Table of Contents

1. What is CIMC aluminum alloy tanker trailer?

2. CIMC fuel tanker trailer specs, capacity and drawing

3. Features of aluminum tanker trailer

4. How to choose CIMC Aluminum Tanker Trailer?

CIMC fuel tanker trailers are mainly used for transport liquid and oil. CIMC fuel tank body is generally made of carbon steel sheet, and it can also be made of aluminum alloy, stainless steel, polyethylene and other materials. CIMC fuel tanker trailer adopt advanced design concept. We can customized the tankers for you according to your request.

CIMC aluminum alloy cement bulker trailer and carbon steel powder material transportation semi-trailer successfully took into account the optimal design of the power system of the main vehicle and the trailer, achieving a perfect match between safety and light weight, and the whole vehicle is more economical, safer, more stable and more beautiful, it is the first choice for the transportation of bulk materials such as cement, fly ash, calcium powder, etc.

Aluminum Alloy Diesel Fuel Tanker Trailer

Aluminum Alloy Bulk Cement Tanker Trailer

Model: 3 axle fuel tanker trailer

Dimension: 11500mm*2500mm*3700mm(the exact size depends on the final design)

Volume: 40000liters

Application: transport Fuel, Oil, Diesel

Tank body:

Material: Aluminum alloy

Tank body and separate compartment plate: 6mm

Compartments: Optional

Manhole cover: Aluminum alloy API manhole cover 500mm (diameter)

Discharge valve: Diameter is 3 or 4 inch

Bottom valve: Aluminum API Pneumatic Bottom Valve

Tanker body test: Hydrostatic test to 5 psi (35 Kpa) on each compartment

Chassis:

Axles: 3 units, FUWA/BPW/CIMC/other

Landing Gear: JOST brand

King Pin: JOST brand 2.0 or 3.5inch(bolted or welded type)

Suspension: Mechanical suspension or air suspension

Brake System: WABCO

Tire: 12.00R22.5/315.80R22.5/11.00R20/12.00R20 brand can be optional

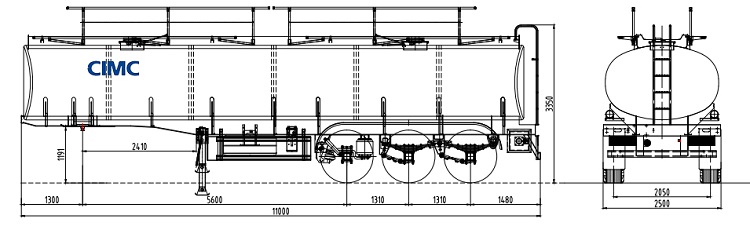

CIMC Aluminum Alloy Tanker Trailer drawing

(1) more economical

Low fuel consumption and steady income increase

The European standard aluminum alloy material is selected, and the curb weight is 1.5 tons lighter than ordinary carbon steel powder tanker. According to a research report by the European Aluminum Association, for every 100 kilograms of light a vehicle, fuel consumption per 100 kilometers can be reduced by 0.6 liters.

(2) Fast unloading, little surplus

The curvature and fluidization angle of the cylinder are optimized, and the unique tank throat tubular fluidized bed compaction technology is adopted. The discharge time is 5 to 10 minutes faster than similar competitors, and the remaining volume is about 100 kg less than similar competitors.

(3) Big brand high value preservation

The price of second-hand models in the market is higher than similar competitors. Aluminum alloy has high corrosion resistance, and there is no damage to the tank body when it reaches the mandatory scrap period.

(4) more secure

Equipped with double safety valves, double insurance is more assured, and the pressure control in the tank is safer.

The aluminum tanker trailer tank-top walkway platform that meets the international standards, and the fully enclosed fence, ensure the safety of the operating personnel regardless of night work, rain, snow, and wetness.

The ladder is equipped with extra-wide pedals, so you can take every step with peace of mind.

Using the overall wiring harness layout, the circuit is unimpeded and short-circuited.

Using forged aluminum ring, the material strength is about 30% higher than that of cast aluminum ring, improving safety.

Optional 360° surround view system, right blind spot monitoring, rear collision avoidance warning, road deviation warning, and intelligent technology for safety escort.

CIMC Aluminum Alloy Tanker Trailer factory

(5) more stable

The core accessories are all selected global leading brands, and the tank body and core components are guaranteed for three years.

Mature and stable manufacturing process system, using industry-leading laser cutting technology, TIG automatic welding technology, 100% reliable quality, stable performance, and improve the product life cycle attendance rate.

(6) more beautiful

The details of the aluminum tanker trailer are designed by first-class artists, comparable to the visual experience of a car.

Unique custom-made tanker trailer stickers, toolboxes, wiring boards and other accessories with unique line art design, simple and stylish lighting layout.

1.Tanker Thickness: The thickness of the aluminum tanker trailer is an important aspect to check. It is normally chosen according to the tank’s capacity. There are standards already set in the industry to guide you in making the right choice. Therefore, don’t think that the one with a thicker wall is the best. It must well-matched with its capacity requirements.

2. The material of Construction: You can choose between stainless steel and aluminum alloy constructions. With a stainless steel construction, your cement tanker will not be easily attacked by rust hence can guarantee a long-life.

3. Common specs for reference: These are specifications that will help you to clearly understand what you need to match your current needs.

4. Know the capacity: This would probably come first in your considerations. How much of cement do you want to transport and for what distance. If you have a lot of stock to transport, it is important you get a tanker with a high volume capacity and strong enough to manage that weight. Getting the most appropriate option for your cement capacity will come as a result of a combination of various specifications. You will not just be looking for the volume needs only.

CIMC Aluminum Alloy Tanker Trailer for Sale

CIMC aluminum tanker trailer adopts a three-dimensional design scheme. Three-dimensional design refers to the use of a computer to represent the actual shape of the product as a three-dimensional model, so that the three-dimensional model can contain more actual structural features, and can truly reflect the structure and manufacturing process of the actual product by simulating the product.

At the same time, computer-aided analysis of the structural mechanical properties of the tank body, and optimization of the structural performance, make the entire tank body more reasonable, so that the tank body can have a longer service life.

After the external shape and internal structure are designed, the cement tanker trailer tank body needs to be painted. The tank body of 3 axle pneumatic sand trailer adopts spray + powder spraying process design, which can make the coating life 5-8 years without fading.

And the weather resistance and corrosion resistance of the paint used can be doubled compared with ordinary paint. The thickness of the coating reaches H level, which is less likely to be scratched. Finally, the preliminary treatment does not contain phosphorus and heavy metal materials, which is more environmentally friendly.

The aluminum tanker trailer design structure of the fluidized bed inside the tank.

The inclination angle of the barrel and side slide of 3 axle cement tanker is greater than 2-3 degrees compared with other tanks in the same industry. This can improve the fluidity of the materials, reduce the residual amount of materials inside the tank and unload the materials as soon as possible. It can reach 1.5 tons per minute.

The discharge port of the tanker trailer body also adopts an enlarged design, which can ensure that the material can be supplied adequately when discharging, and the material can be discharged at the fastest speed. Moreover, the reinforced support of the discharge pipe, using the triangular stability principle, can ensure that During the unloading process, the pipeline has no displacement and has the best stability.