3 Axle 60 Ton End Dump Semi Trailer will be sent to Ghana

3 Axle 60 Ton End Dump Semi Trailer will be sent to Ghana

The Ghana customer found us through a friend's introduction. CIMC's semi trailer quality is trustworthy. All of our end dump semi trailers use high-strength steel, which is more durable and strong in the face of the harsh transportation roads in Africa. The final customer chooses to cooperate with CIMC. Customers are very willing to have long-term cooperation with us. There are many CIMC customers in the Ghana local area, and without exception, they are full of praise for CIMC end dump trailer.

From the production of raw materials to the production process, from employees to design, supply chain, manufacturing, and assembly, all links are strictly controlled. CIMC also provide innovative and high-quality engineering solutions for the transport industry and make it more effective. All models can be made to order and customized to suit your exact requirements and provide the most economical hauling solutions to customers.

3 Axle 60 Ton End Dump Semi Trailer will be sent to Ghana

3 Axle 60 Ton End Dump Semi Trailer will be sent to Ghana

1. The structure of the end dump trailer should be reasonable, and the center of gravity of the chassis should be as low as possible. According to the dump semi trailer's load, cargo type, road conditions and the driver's driving habits, systematic planning and design should be carried out to meet different usage requirements.

2. The materials used should be real. The seemingly identical steels are actually divided into high-strength steel, manganese steel, and ordinary carbon steel. Among them, the high-strength steel is divided into 700, 900, and 980 models. Its durability and strength will gradually increase with the increase of the label. The weight of the body can be gradually reduced, but the cost will also increase.

3. The processing technology of the cimc tri axle end dump semi trailer has to pass, but now with the popularization of mechanical automation, many factories have realized basic automation in the process of vehicle processing, such as blanking, welding, etc., and the production technology has generally been greatly improved. . In addition, after welding and forming, it is necessary to perform processes such as surface sandblasting and rust removal, so as to better increase the adhesion of the paint.

3 Axle 60 Ton End Dump Semi Trailer will be sent to Ghana

3 Axle 60 Ton End Dump Semi Trailer will be sent to Ghana

The spraying of the paint should be uniform and the coverage should be comprehensive. The paint is divided into alkyd paint and high-end polyurethane paint. Considering the structural characteristics of the 3 axle end dump trailer, the spraying method is mostly a semi-automatic method combining manual and machine.

4. Reasonable lightweight matching of the whole vehicle. The dump industry also follows the principle of lightweight and more goods. However, considering the special nature of the work of the end dump semi trailer, lightweight must not be blindly reduced.

The lifting hydraulic system must be stable, the oil circuit design must be reasonable, and the cylinder lifting must be synchronized. The hydraulic system is the power source for the end dump trailer. It is composed of pumps, valve groups, fuel tanks, pipelines, and cylinders. Such as the main original components, the hydraulic system must operate stably to ensure the normal progress of unloading.

5. In addition, the installed tires need to have a national three-guarantee commitment. This model generally matches 12.00 tubeless tires. High-quality tires are an important guarantee for driving safety. Only brand-protected tires can better protect driving safety.

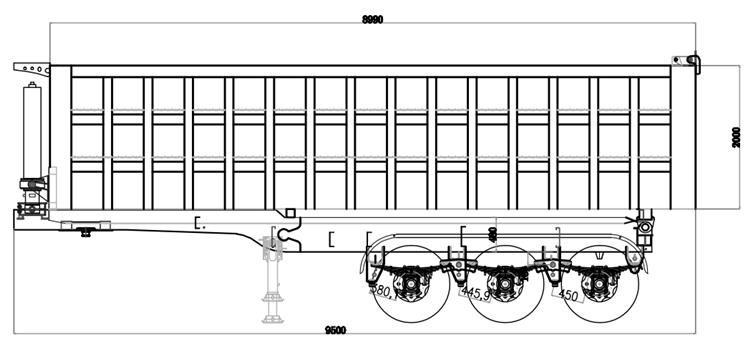

Drawing of 3 Axle 60 Ton End Dump Semi Trailer

Drawing of 3 Axle 60 Ton End Dump Semi Trailer