CIMC 3 Axle 35CBM Cement Powder Truck is Ready for Mali

CIMC 3 Axle 35CBM Cement Powder Truck is Ready for Mali

Mali customers found us CIMC Factory when they searched for power tanker on Google for a new project. The customer also had some knowledge of Chinese semi trailer suppliers before, and knew that CIMC is a big brand in China's trailer industry. At the same time, he also found some good manufacturers. When he communicated with our salesman, our salesman was anxious about what he was worried about, thought about what he thought, and solved some problems for the customer. The customer thinks that we are worthy of being a well-known expert in China. So the customer firmly chose us to produce this batch of power tankers for him. We also lived up to the trust of our customers, and produced bulk power tankers to a high standard, and now these cement powder trucks are ready to be sent to Mali.

CIMC 3 Axle 35CBM Cement Powder Tankers is Ready for Mali

CIMC 3 Axle 35CBM Cement Powder Tankers is Ready for Mali

1. Modern computer-aided design and force analysis can ensure longer product life

The tank body of the CIMC powder tanker adopts a three-dimensional design scheme. Three-dimensional design refers to the use of computers to represent the actual shape of a product as a three-dimensional model, so that the three-dimensional model can contain more actual structural features, and can truly reflect the structure and manufacturing process of the actual product by simulating the product.

At the same time, the CAE force analysis was adopted, and the structural mechanical properties of the tank were analyzed with computer aids, and the structural properties were optimized, so that the stress of the entire tank was more reasonable, so that the tank could have a longer service life.

CIMC 3 Axle 35CBM Cement Powder Tankers Truck is Ready for Mali

CIMC 3 Axle 35CBM Cement Powder Tankers Truck is Ready for Mali

2. The exterior design of the tank should not only be beautiful, but also practical

After the design work of the tank is completed, the actual manufacturing work is carried out. CIMC adopts laser cutting and blanking, which can improve the accuracy to 0.01mm, and the mirror incision is formed at one time, which can reduce the cutting hot-melt area as much as possible, so that the elements of the steel plate remain unchanged, the rigidity will not be lost, and the phenomenon of stress concentration will not occur.

Then, using the automatic CNC plate rolling machine control, the cylinder is formed at one time, the inside of the plate will not be damaged, and the forming quality is stable and reliable.

The next thing the rollers need to do is team up. This cement powder truck of CIMC adopts a frame-type teaming process, so that the left and right rollers are connected. Such process equipment can ensure that the tank body will not be deformed during the teaming process and has a beautiful appearance.

Moreover, the size of the cylinder body is exactly the same as the design size, which can make the cylinder body have an ideal force layout, so that the tank body will not be easily cracked.

After the tank is assembled, it is the welding work. A good welding process can not only keep the welding seam of the tank body beautiful, but also ensure that there will be no concentrated stress at the welding point of the steel plate, and keep the steel plate of the tank body with good strength.

The tank body of the CIMC powder tanker adopts an automatic welding process, which is welded on one side and formed on both sides, so that the tank body has better strength.

After the shape of the tank is determined, it is also necessary to accurately position the tank. Only accurate positioning can avoid problems such as traction pin wear, suspension tire wear, trailer drift and center of gravity offset as much as possible. The tank body of this model adopts the bottom price horizontal positioning platform with the function of automatic height adjustment, which can ensure that the trailer bottom frame and the tractor saddle can be completely matched according to the height difference of the tractor saddle of different brands.

3. The tank body is unloaded quickly and the residual material is small, and the internal design should be professional

The fluidized bed design structure inside the tank. The inclination of the barrel and side slide of this powder tanker for sale is 2-3 degrees greater than other tanks in the same industry, which can improve the fluidity of materials, reduce the residual amount of materials in the tank and unload materials as soon as possible, among which the unloading speed is the fastest As fast as 1.5 tons/min. The discharge port of the powder tank is also designed to be enlarged, which can ensure that the material can be adequately supplied during unloading, and the material can be unloaded at the fastest speed, and the reinforced support of the discharge pipe, using the principle of triangular stability, can ensure During the unloading process, the pipeline has no displacement, and the stability is the best.

CIMC 3 Axle 35CBM Bulk Powder Tankers are Ready for Mali

CIMC 3 Axle 35CBM Bulk Powder Tankers are Ready for Mali

4. The painting process is very important, not only to ensure the quality of the car paint but also to pay attention to environmental protection

After the external shape and internal structure are designed, the tank body needs to be painted. The tank body of CIMC is designed by spraying and powder spraying process, which can make the coating life 5-8 years without fading. In addition, the weather resistance and corrosion resistance of the paint used can be doubled compared with ordinary paint, and the coating thickness reaches H level, which is less likely to be scratched. Finally, the pre-treatment does not contain phosphorus and heavy metal materials, which is more environmentally friendly.

5. Power tanker piping design needs to pay attention to details, details determine the success or failure of the product

Finally, the arrangement and assembly of the piping outside the tank. In terms of piping, special attention should be paid to details. The ball head is designed with stainless steel, which is both beautiful and usable. The reinforced outer bracket can make the tank withstand better force. Laser welded seam, no stress concentration, make the life of the tank longer.

6. Inspection work is a necessary part. New bulk power tankers can only enter the market if they meet the inspection standards.

When a new cement power truck is completed, it can only be regarded as a qualified product after passing the inspection of various strict standards. CIMC has test towers, complex road conditions, and vehicle testing center test sites, which can accurately test the unloading speed of the tank and the optimal positioning size of the residual amount, the stability of the vehicle during driving, and the braking performance of the vehicle. Safety performance, only after the performance of the vehicle has reached the national standard, can it enter the market for card users to use.

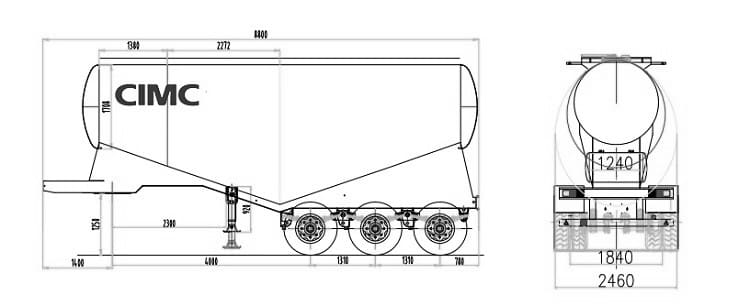

Drwaing of CIMC 3 Axle 35CBM Cement Powder Tankers for Sale

Drwaing of CIMC 3 Axle 35CBM Cement Powder Tankers for Sale